Silvec’s Surface Treatments

▲ Click for more details ▲

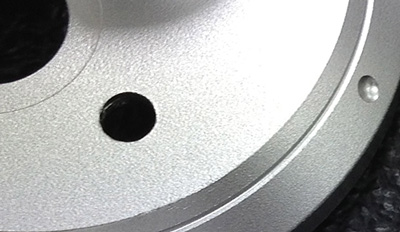

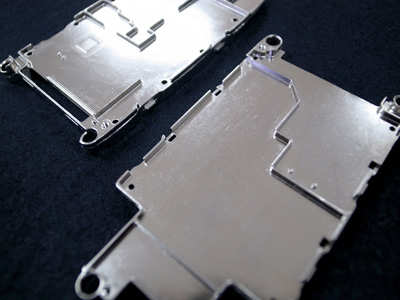

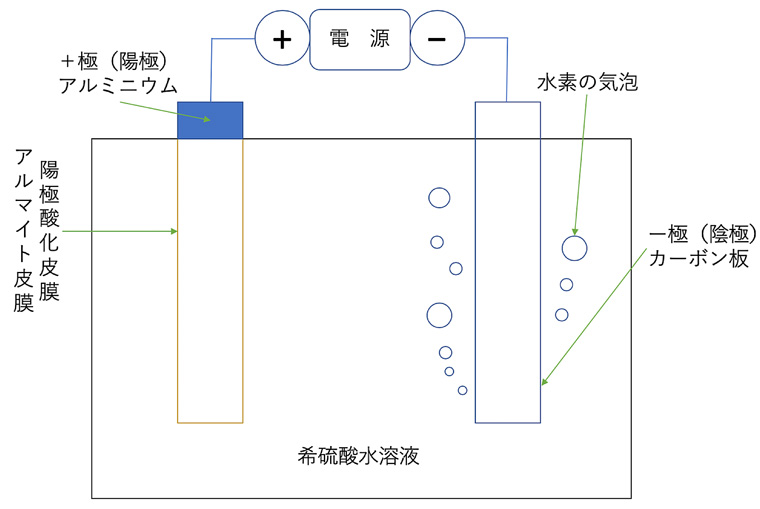

Anodizing |

|

Alumite is the process of growing an aluminum oxide film on the surface of an aluminum material by passing a direct current with the aluminum material as the anode (+) and the carbon plate as the cathode (-). Charactristics |

|

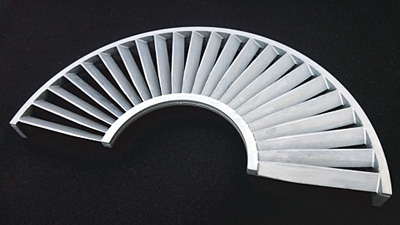

► Normal Anodizing |

|

|

|

|

|

|

|

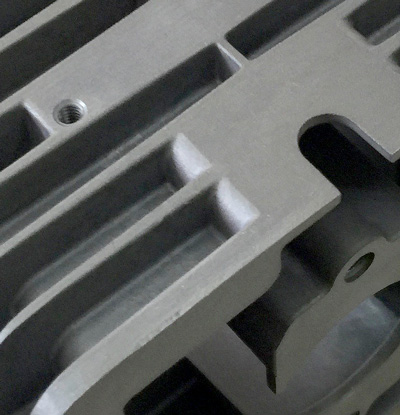

► Hard Anodizing |

|

|

|

|

|

|

► Aluminum Alloy Anodizing Adaptability |

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mark A:Very Good B:Good C: Avegrage D:Unfit JIS H 8601 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chemical Treatment |

|

Trivalent chromium chemical conversion film is generated through a chemical reaction. With the film being ~1μm thick, there is practically no dimensional change.

|

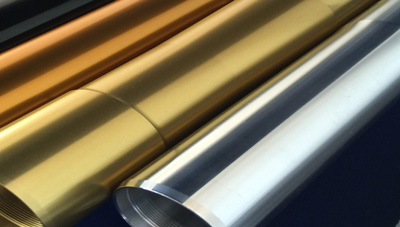

Plating |

► Plating Menu |

|

|

|

|

► Compatible Materials |

|

|

|

|

*All of our products are RoHS appricable as well as MSDS available.

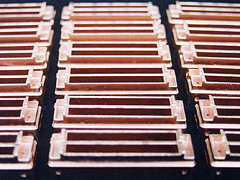

► Method |

|

|

|

|

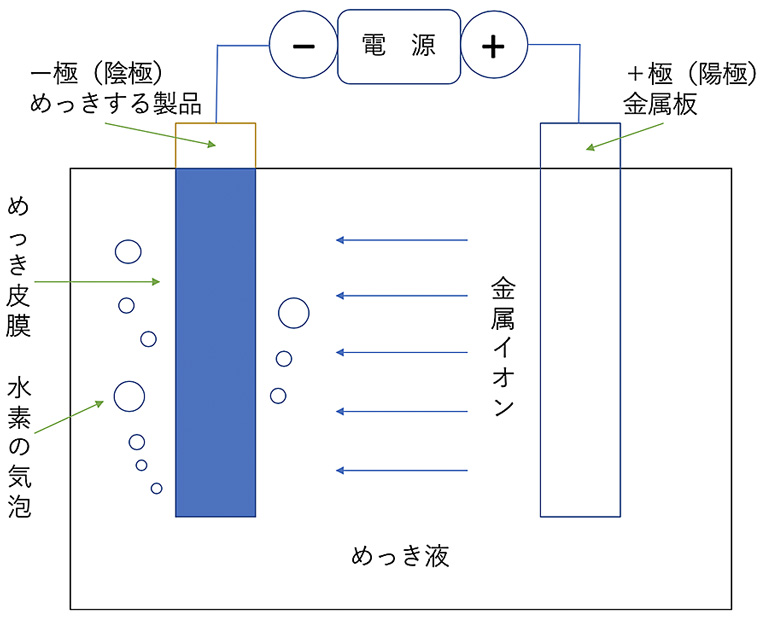

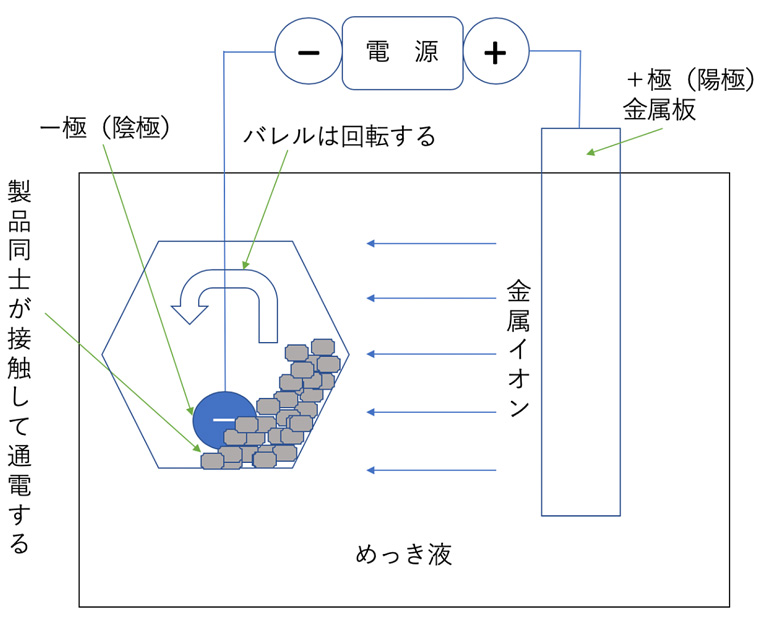

The plating work is roughly divided into two methods. 1) using a jig 2) using a barrel.

Using the jig, each product is set on the jig, and plated. Using the barrel, the product is placed in the barrel and plated while rotating.

We can perform highly accurate barrel plating on fine products, products that are easily deformed, and products that are easily entangled.

JIG Plating |

BARREL Plating |

|

|

|

Merits ・Large sizes can be plated |

Merits ・No jig contact mark ・Lower unit price |

|

Demerits ・Jig contact traces are generated |

Demerits ・Large size products cannot be barreled |

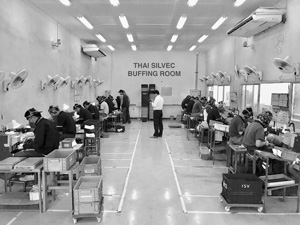

Polish / Satin Finish |

| Types | Materials | Characteristics | |

| Polish | Chemical Polishing | Aluminum, Iron | Polishing by immersion in chemical polishing liquid reduces overall dimension. |

| Buffing Polishing | Zinc die casting, Aluminum、Brass |

Physical polishing of the surface reduces surface dimension. | |

| Barrel Polishing | Aluminum, Iron、 Zinc die casting、SUS |

The process differs depending on the purpose (gloss, burr removal, surface modification, etc.). The contact surface with the media is polished resulting in reduced dimensions. | |

| Satin | Chemical Satin | Aluminum | The process differs depending on the purpose (gloss, burr removal, surface modification, etc.). The contact surface with the media is polished resulting in reduced dimensions. Shot blasting may increase product dimensions due to changes in the surface of the product. |

| Shotblast |

Aluminum、 |

||