Coating

Our company is a fluorocarbon resin coating of OKITSUMO which is heat-resistant paint industry No.1. Manufacturing and selling in Thailand. Trust processing of a surface treatment use navalon and corresponding to the demand of a visitor's use, the purpose, a material, etc.

|

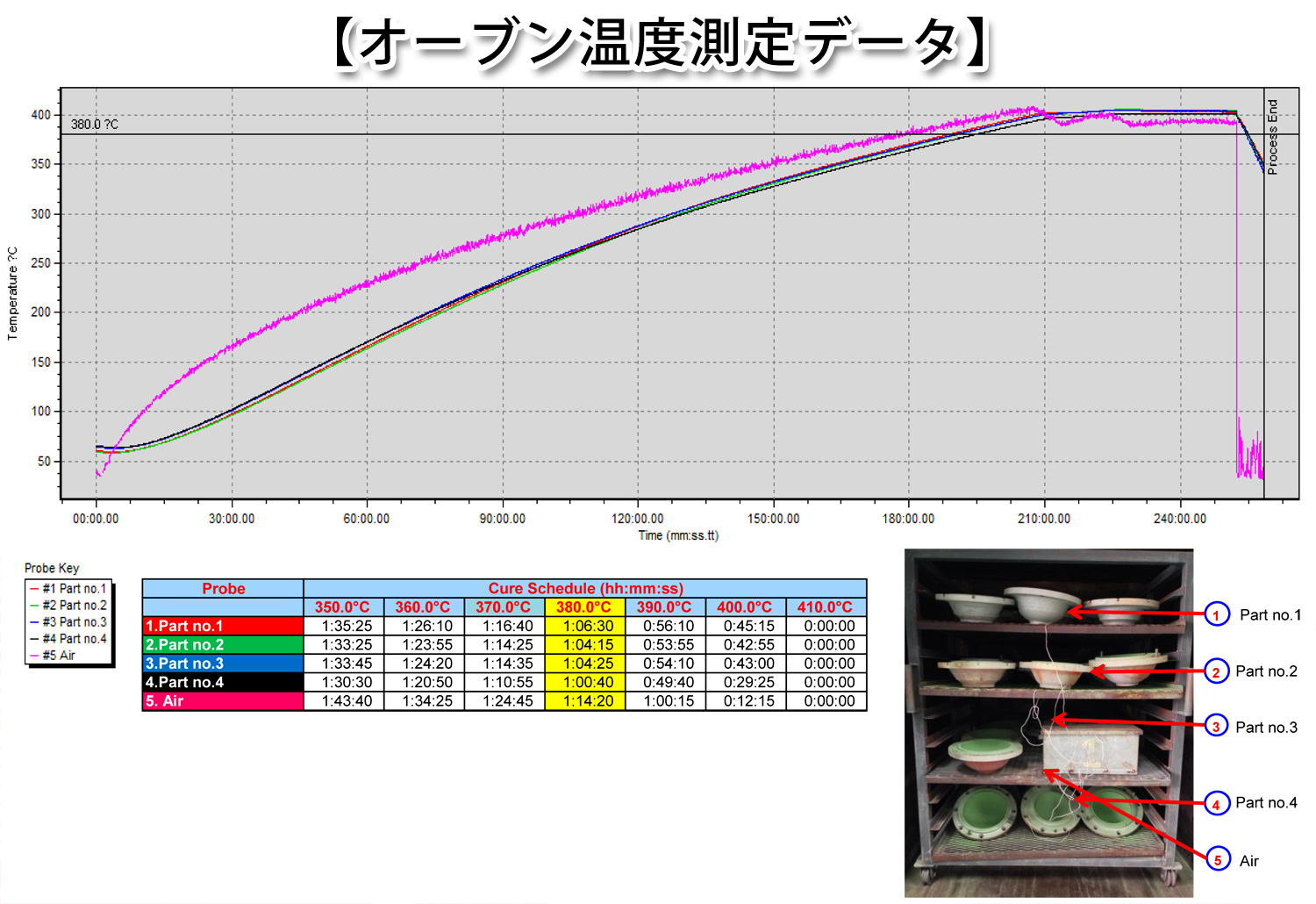

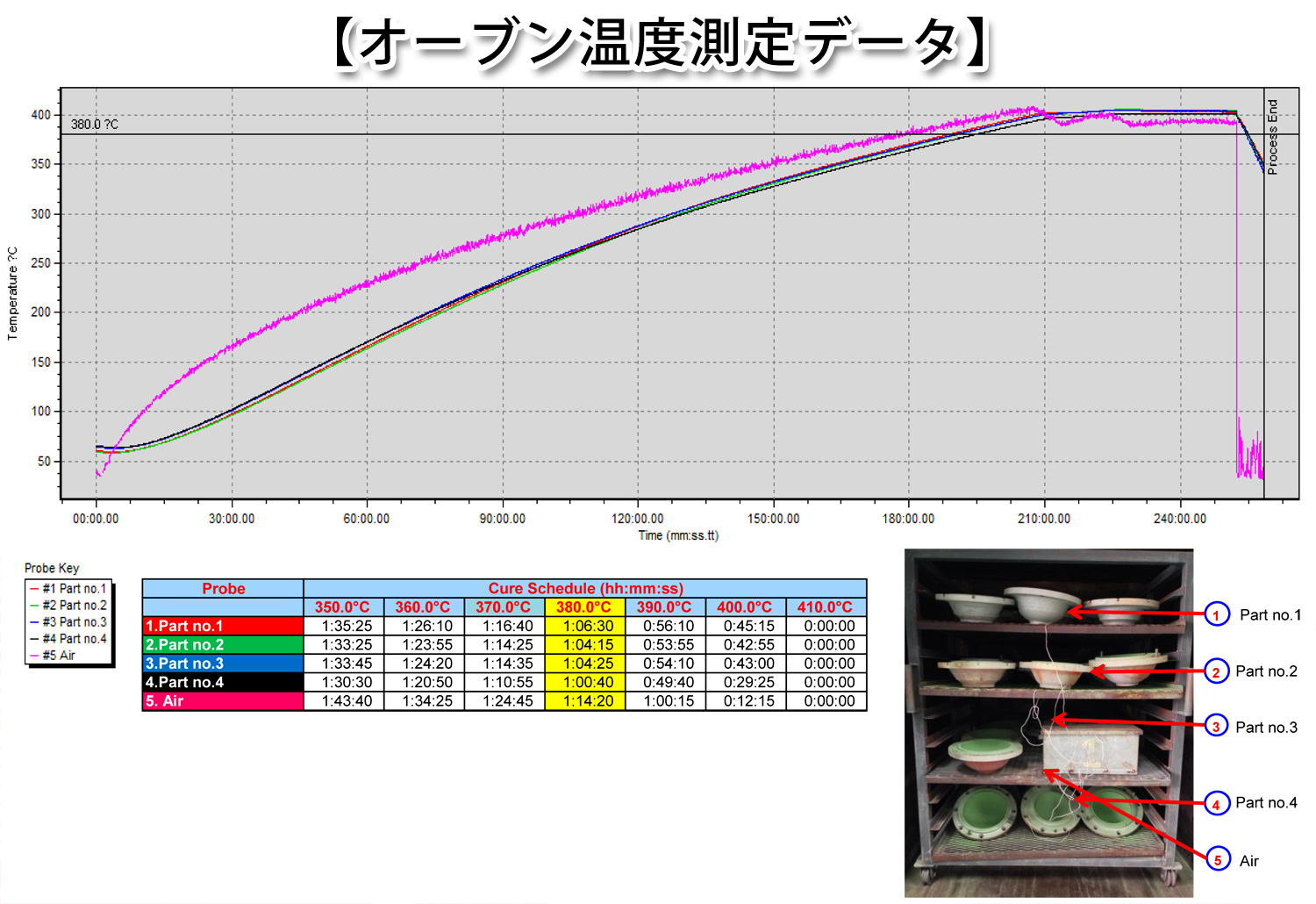

Confirm with heat whether the heat is reliably transmitted to the processed product in the oven.

※ It is the point that becomes the most important in seizing

(You can click and enlarge it for viewing.)

|

Batch oven 3 units

|

Fluorine resin is generic of synthetic resin(plastic) that combined fluorine atom and carbon atom.

As the properties are different by atom combined and fluorine resin has many different types.

|

|

Features

|

|

|

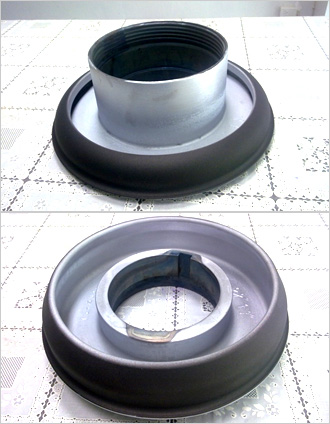

① Demold

■The most popular usage of fluorine resin

Demold is preventing cohesion and adhesion in other words, nonviscous property. And it is way to be often used in fluorine resin.

Application of fluorine resin coating in relation to food is for fry pan, is famous but in relation to industry it is used metalic mold for rubber material / urethan etc.

■Coating for demold

PTFE that polytetrafluoroethylene, polymerized is used for mold lubricant.

And FEP and PFA etc. are also used.

|

|

|

|

② Corrosion resistance

■Characteristics of chemical resistance/Corrosion resistance/ Weathering resistance

Fluorine resin has the good weathering performance to be applied at tough environments. And it is used in wide range of fields. By preventing corrosion with weathering performance, it can be applied at chemical plant to protect equipments, pipes and so on.

■Fluorine resin coating for Corrosion-resistance

"Copolymer FEP and PFA of tetrafluorethlene and hexafluorethlene(both of fluorine resin raw material)", and "copolymer(ETFE) etc. of tetrafluoroethylene(C2F4) and ethylene(C2H4)" are used in corrosion resistance.

|

|

|

|

③ Lubrication

■Coefficient of friction of fluorine resin is Low.

Fluorine resin keeps good lubrication performance without lubricant oil.

And it’s applied in wide range field. For example, if you coat fluorine resin to screw, it will not crack suddenly.

■Coating for Lubrication

Denatured PTFE is mainly used to lubrication.

|

|

►see all Case Studies

|

|

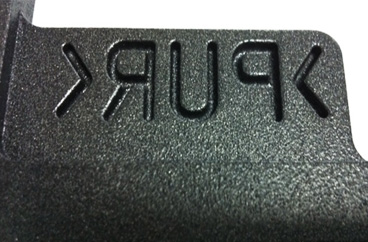

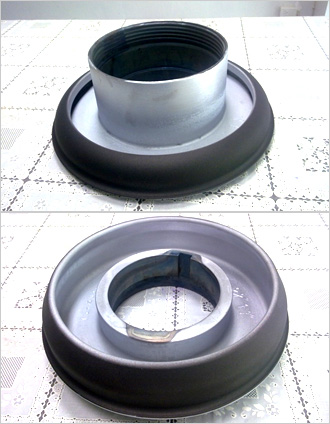

Processing non-adhering [ concavo-convex ]

|

|

|

It is coating which has a track record by the bonding process .

Unlike fluoro-resin processing, the non-adhering way of thinking is [ a surface feeling of ZARAZARA] a conclusive factor.

►see all Case Studies

|

|

|

|

Zinc flakes antirust coating

|

It is chromium-free super-antirust coating which has gained popularity .

It is being observed as antirust processing of the next generation which changes to plating, and adding topcoat,

I demonstrate the compounded characteristics, such as a lubricative rise and stability of torque.

Our company, is processed using ZINTECH® of ATOTECH.

|

|

|

Fluoride eutectoid plating

|

It is lubricous plating which has gained popularity very much since the service start.

It is plating which has the lubricity of PTFE in addition to the hardness rise of the material by plating.

Unlike paint, a uniform tunic is formed also in a narrow crevice.

►see all Case Studies

|