News

October 22-25, 2025:

|

|

MECHATRONICS TECHNOLOGY JAPAN 2025 Date : October 22-25, 2025

We look forward to seeing you at our booth! |

Super engineering plastic: Ultrasonic deburring and cleaning of PPS |

|

PPS resin is one of the high-performance engineering plastics known as “super engineering plastics” among thermoplastic resins. PPS is an abbreviation for “polyphenylene sulfide”. It is used in a wide range of fields due to its excellent heat resistance, cold resistance, and chemical resistance.

However, PPS resin is prone to gas generation, and the resin tends to get caught in the mold parting line, causing burrs to form.

When PPS molded products go from simple shapes to very complex shapes, the burrs that are generated cannot be removed using conventional shot blasting, etc., and the residual shot blasting material becomes a problem.

Most of the burrs generated by thermoplastic materials are very fine, and our powerful ultrasonic deburring equipment can remove them cleanly, while also cleaning the surface at the same time. It is possible to clean the surface precisely while deburring a large number of items at the same time in water.

The ultrasonic deburring and cleaning machine for PPS (40% glass fiber) is one of our main products, and is shipped all over the world.

by shibano

|

|

Rocket engine and metal 3D molded nozzles

|

|

Blue Star R&D Co., Ltd. has developed and delivered ultrasonic casting sand removal equipment for aluminum casting parts. The company has also standardized and marketed ultrasonic deburring equipment that removes burrs generated after machining of aluminum die-cast products such as engine heads, engine blocks, and transmissions. These have been standardized and marketed domestically and internationally as the “MARS Series” of vacuum pre-processing type ultrasonic deburring systems and ultrasonic casting sand removers.

In recent years, requests for removal of residual fine powder in internal cooling microtubes, heat exchangers, and cross flow paths for metal 3D have been increasing, so the MARS series was improved and released as the PERION-AM series dedicated to internal metal powder removal for metal 3D. The shape of AM's internal tubules varies widely, but some of them are less than 1mm in diameter, and there are many secrets regarding the exact flow paths and internal tubules that we are not able to understand. In some cases, the AI design around aircraft engines has become so complex that human designers are unable to understand the distribution of the inner and inner tubing.

In any case, the product will not become a product unless the metal powder left inside is removed. Air blowers and high-pressure water are not sufficient to remove them. Therefore, we have combined the ultrasonic freezing sand removal and ultrasonic deburring technologies that we have cultivated over many years to remove residual metal powder in the inner fine tubing.

It is necessary to efficiently transmit ultrasonic waves through the metal 3D to generate ultrasonic cavities (microvacuum nuclei) inside the microtubules. Therefore, the irradiation method, such as the irradiation angle, involves some trial and error. When the nozzle of the combustion section of a rocket engine is made smaller and lighter by metal 3D manufacturing, the cooling tube through which the refrigerant passes inside is naturally a complex structure. Therefore, the removal of residual metal fines is an essential condition. We also specialize in ultrasonic removal of residual fine particles in metal 3D molded rocket engine nozzles/internal fine cooling tubes, the result of our accumulated technology and experience since the F1 era.

Experiments are accepted at any time, so please inquire separately.

by shibano

|

|

February 2024:

|

|

Hyaluronic acid is an essential component for storing moisture and keeping skin fresh. Human skin is composed of three layers from the outside: epidermis, dermis, and subcutaneous tissue, of which hyaluronic acid is contained in the dermis layer and is responsible for moisture and elasticity. However, the amount of hyaluronic acid decreases with age, causing skin dryness and wrinkles. Hyaluronic acid has a large molecular weight (700,000-2,000,000 or more) and is not easily absorbed into the body. In order to hyaluronic acid to penetrate through the epidermis to the dermis layer, it is necessary to reduce the molecular weight of hyaluronic acid. |

|

October 2023:

|

|

Ultrasonic metal powder removal system for metal 3D laminated molding in extremely complex internal fine sedimentary structures. Successful internal precision cleaning of a wide variety of metal 3D products.

|

|

September 2023:

|

|

The latest metal mask cleaning machine will go on sale in September 2023.

|

|

July 2022:

|

|

The development of metal 3D precision molding technology is remarkable, and it seems that it has been evolving more precisely, more complicatedly, smaller and smaller.

On the other hand, what is important is the fine metal powder left behind inside. If this is not removed, the product will not be completed.

Blue Star R & D's ultrasonic waves completely clean and remove the metal dust inside. The powerful ultrasonic waves that can remove even burrs are sufficiently transmitted to the inside when irradiated from the outside of the metal 3D molded product, and clean the metal fine powder remaining in the internal flow path.

If you have any problems, please feel free to contact us.

|

|

July 2022:

|

|

As the delivery record of ultrasonic barrel equipment (deburring, polishing, cleaning, simultaneous processing) increases, the number of inquiries and test requests to our company has been increasing rapidly.

The ultrasonic barrel does not use abrasive compound. A large amount of parts are put directly into a hexagonal basket and process to deburr, polish and clean them while irradiating them with ultrasonic waves for deburring.

Objects are various metals, plastics, ceramics, etc. It differs from traditional barrels in the following points.

[Features]

As a result, labor costs, man-hours can be significantly reduced, quality can be improved, and major environmental improvement measures can be taken.

|

|

March 2021:

|

|

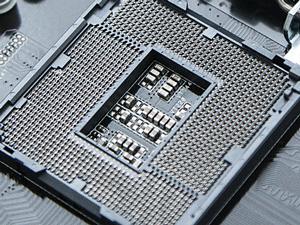

CPU sockets, IC sockets and LSI sockets have been developing and miniaturized rapidly in recent years. It becomes more and more complicated and mass production is required. Their materials are high-performance plastics such as PEEK. Deburring for them are difficult with the conventional method.

With our equipment, it is possible to process deburring one to several thousand at once.

We recommend our Ultrasonic deburring and cleaning equipment for automation. Only water (pure water) is used. Easy to dry.

Please check the performance of ultrasonic deburring and cleaning by trying our deburring test with your deburring items. Experiments are accepted at any time.

|

|

Please feel free to contact us if you need any further information.