Pursuing Zero Defects (Zero-Defects) Contributing to the improvement of quality assurance capabilities and the promotion of automation in Thai factories

─ For companies considering factory automation ─ |

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

─ For companies that are concerned about quality control ─ |

||

|

|

|

|||

|

|||

─ For companies looking for suppliers to reduce costs ─ |

||

|

|

|

|

|

|||

|

|||

News & Events |

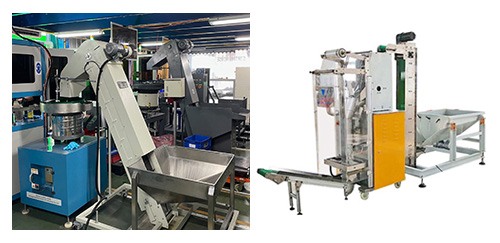

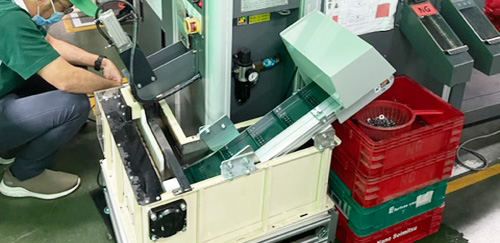

NANO SEIMITSU not only sells automatic sorting machines, but also offers the High-speed AOI sorting service with TRIGO QUALITY SERVICES and Hanshin Neji (Thailand).

*We are continuing our sorting service at our automated sorting house in Bang Phli, and from September, we expanded to three locations in Rayong, Chonburi and Samut Prakan. Please contact us to discuss your needs in an area convenient to your company. |

Weekly updates! Your Partner in Quality |

|

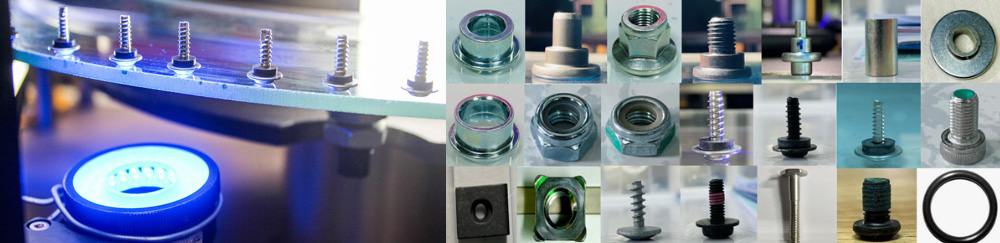

For Sorting Similar-Shaped Parts with Different Part Numbers, Consult NANO (Feb 2, 2026)This week, we introduce mixed-part inspection using automatic sorting machines. Image-based inspection is not limited to dimension or deformation checks alone. It is also highly effective in detecting mixed parts with different part numbers or similar sizes. |

|

Reducing Cost While Protecting Quality - A New Proposal for Semi-Automated Visual Inspection (Jan 26, 2026)This week, we introduce a semi-automatic gear chipping inspection machine designed for sintered parts. This solution is ideal for companies that do not require full automation at this stage. By automating only the inspection process, the system reduces initial investment while preventing defect leakage caused by human error. |

|

From Human Vision to AI (Jan 19, 2026)Medicines and supplements that we consume daily are manufactured and inspected under strict safety standards. Today, 100% automated visual inspection using image processing has become the industry standard. |

|

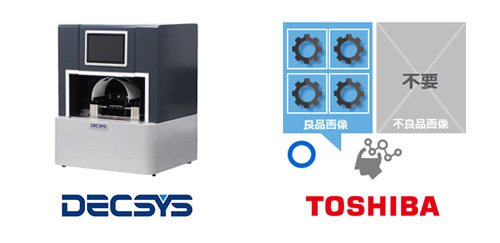

When conventional image inspection reaches its limits, adding AI transforms visual judgment. (Jan 12, 2026)In visual inspection sites, have you ever hesitated over whether something is OK or NG? |

|

Wire-Type Automatic Sorting Machine (Jan 5, 2026)Are you facing challenges with inspection accuracy or labor shortages in bolt inspection processes? The Wire-Type Automatic Sorting Machine introduced here is a next-generation solution that delivers significant improvements in processing speed, setup efficiency, and labor reduction compared to conventional systems. |