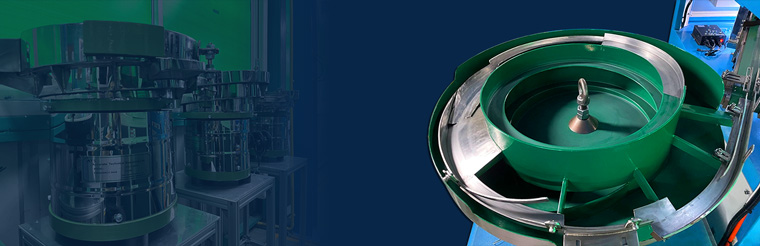

Custom Parts Feeder Features |

► Various materials such as resin, rubber, metal, spring, etc., and customization |

Specifically, bowl materials and coatings are selected that best suit the characteristics of the workpiece (material,

weight, and size).

Next, the vibrating body and attachments are designed in consideration of the balance, posture, and feeding speed of the workpiece.

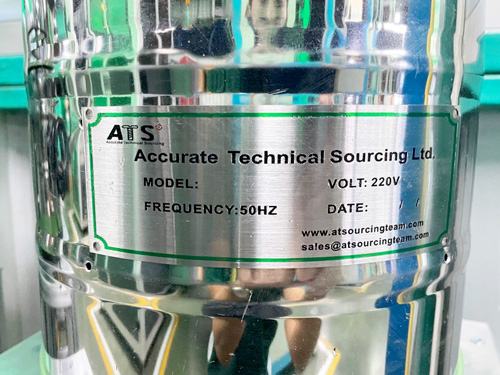

► Competitive pricing through proprietary network |

The actual design and manufacturing are handled by our nano-precision partner ATS and its partner company (Shanghai, China). As a parts feeder supplier for UAZNC, a manufacturer of image sorting machines handled by our company, the company has been trained through mass production, and its track record, technical capabilities, and know-how are comparable to those of Japanese manufacturers.

The price of a custom parts feeder is almost half of that of a Japanese manufacturer's custom parts feeder, which is usually in excess of 1,000,000 yen per unit.

► Security Guarantee |

Naturally, the product comes with a manufacturer's warranty and after-sales maintenance by our company, so you can use the product with peace of mind.

Case Studies |

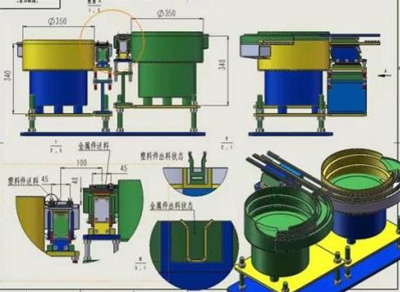

Replacement of old and new parts feeders |

|

Since this parts feeder is connected to a brake hose inspection system, it is necessary to orient the workpieces and feed them stably in a fixed direction. When manufacturing equipment is transplanted from Japan, there are often sites where the dimensions, shape, equipment layout, etc. have been modified on site in various ways, and additions and additions have been made to the equipment, so that it has not retained its original form. We will responsibly handle any site from parts feeder manufacturing, installation, and installation to mass production start-up. |

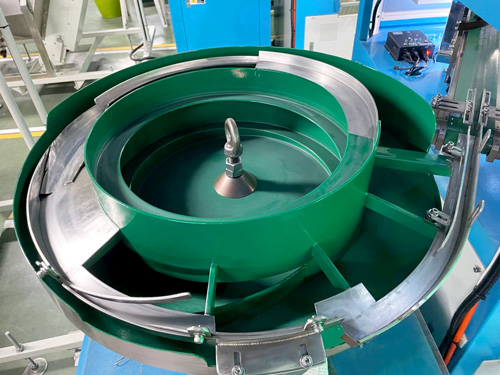

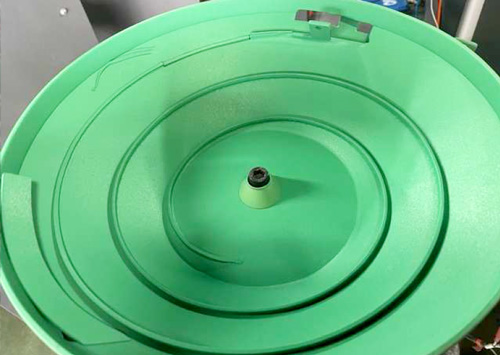

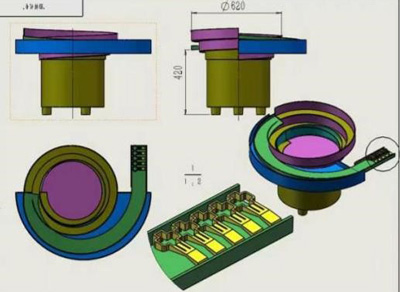

Rotary Parts Feeder |

|

Standard sizes are available in rotary bowl diameters of φ450/φ600/φ800 mm (φ600 mm in the video).

|

Parts feeder for springs & automatic sorting of wire springs |

|

In addition to parts feeders, image sorting of spring products is also possible. Even with complex shapes, the machine can reject even the most ridiculous defects such as breakage, deformation, mixing of different products, and abnormal dimensions by making full use of automatic position compensation and reversal functions. The machine can also be used to reject the most serious defects, such as broken, deformed, mixed, or dimensionally abnormal parts. |

Work Stocker Features |

► Scratches and dents after CNC lathe exit and centerless grinding |

Prevents dents and scratches caused by contact between workpieces, drops, etc. when discharging machined workpieces from NC lathes, through-feed grinding, inspection equipment, etc. It is also ideal for reducing the number of defective products and preventing scratches during unmanned operation, and can be used with all types of machines and equipment.

► Both machine-installed type and stand type are available (can be used according to the facility) |

► Contributes to low cost and cost reduction |

NanoPrecision's workstockers are manufactured in China under the supervision of our partner ATS in China.

Compared to products made by Japanese manufacturers, our products can reduce costs by nearly 40-50% per unit. We have received comments from our customers that they have been able to cut their costs by nearly half by replacing other companies' products.

■Price・・・ Machine installation type: 56,000 THB Stand type: 63,000 THB

※The above prices are for the standard size (height 222.5 mm x diameter 385 mm).

► Other features |

Case Studies |

Countermeasures against dents in brass and aluminum parts (VT Company) |

|

Appearance defects frequently occur in the machining of brass and aluminum parts. Most of them are scratched near the exit of the automatic lathe or in handling before inspection. |

★Contact us for a quote on custom parts feeders and workpiece stockers.★

First, please contact us and prepare a sample of the target workpiece. We will work with the manufacturer to finalize specifications for the workpiece material, shape, posture, feeding speed, etc.

It is also possible to use the drawings of an existing machine and manufacture it at a reasonable cost, We can also provide consultation for parts feeder + next process equipment (automatic assembly, inspection, and packaging machines) together.

For workstockers, you may simply try out the demo machine.

Please feel free to contact us.