NANO SEIMITSU not only sells automatic sorting machines, but also offers the High-speed AOI sorting service with TRIGO QUALITY SERVICES and Hanshin Neji (Thailand).

*We are continuing our sorting service at our automated sorting house in Bang Phli, and from September, we expanded to three locations in Rayong, Chonburi and Samut Prakan. Please contact us to discuss your needs in an area convenient to your company.

|

► What products can be inspected? |

Metal parts (various shapes such as bolts and nuts can be judged), rubber, resin, wood, etc.

Reliable detection of product dimensions, deformations, and contamination with foreign materials.

(Example of sorting service parts we undertake)

► Examples of sorting services |

Sorting service for odd-shaped BUSH nuts |

|

Equipped with multiple high pixel CCD cameras, it captures images of the workpiece from the top, bottom, side, and all around. |

|

use |

Automatic sorting of odd-shaped BUSH nuts |

|

cycle time |

200 pcs /min |

|

output |

Approx. 100,000 units /day (1 shift) |

Automatic sorting of special clips |

|

It can detect not only dimensions, deformation, and mixed products, but also burrs and chips, as long as they can be captured by the camera. Once NG is set, it will not miss any NG, so it is very suitable for sorting monotonous items. |

|

use |

Image sorting of automotive connector lock parts |

|

cycle time |

150 pcs /min |

|

output |

50,000-60,000 pieces /day (1 shift) |

Image inspection of plastic products and plastic parts |

|

The system can sort at a speed of 100 to 150 pieces per minute, checking for filling defects (short shots), burrs, other dimensional abnormalities, and the presence or absence of assembled washers, which are often seen in resin molded products. Moreover, automatic sorting is faster, cheaper, and more accurate than human operation. |

|

use |

Image inspection of industrial plastic fasteners |

|

cycle time |

100 to 150 pieces /min |

Full image inspection of O-rings |

|

It has a two-stage structure that reverses from the belt to the glass table to inspect both sides, and is equipped with four cameras manufactured by Allied Vision of Germany to detect cracks, chips, burrs, and dimensional abnormalities. |

|

use |

Full inspection of O-rings & oil seals |

|

Target Work |

Outer diameter 7mm - 40mm |

|

cycle time |

Approx. 200 pieces /min |

|

output |

Approx. 100,000 units /day (1 shift) |

► What is the cost and delivery time? |

We will contract sorting services for about 5,000 BAHT for 8 hours of operation per day. (Automatic sorting unit price: 0.1 THB~ / PC)

Depending on the cycle time of product inspection, 50,000 to 100,000 pieces can be sorted per day.

► What is the detection accuracy? |

The repeatability is +/- 1 pixel (at a speed of 200 to 300 pieces per minute), which is about 8 microns per pixel, so if you factor in 10 times 8 microns plus repeatability, you can automatically sort at 100 microns or more with no problem at all.

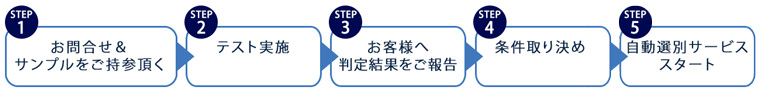

► Transaction Flow |

► Quotes and inquiries for sorting contracting and agency services |

Please feel free to contact us for more information.

★TRIGO QUALITY SERVICES (Thailand) Co., Ltd. Contact Informarion★

|

JAPANESE |

Mr. Yamazaki |

061-820-4530 |

|

ENGLISH |

Thanawat Phutwai |

089-834-8188 |

|

THAI |

Siriwan Rungarunchotchuang |

081-410-6936 |

★Hanshin Neji (Thailand) Co.,Ltd. Contact Informarion★

|

JAPANESE |

Mr. Yamazato |

062-357-7833 |

|

ENGLISH / THAI |

Mr. OH |

098-137-4626 |