Peripheral equipment fine bubble generator GRIND-BIX |

- Change bubble, propose new common sense of grinding -

Structure of GRIND-BIX

Feature

Feature

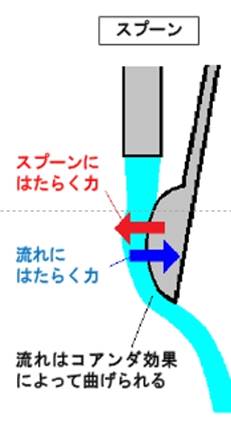

・Coanda effect improves coolant / grinding fluid permeability

The swirling flow jet derived from the internal structure of GRIND - BIX ensured the grinding coolant liquid to spread to the tip of the abrasive grain by the Coanda effect, greatly improving the cooling capacity. As a result, cutting depth of 5 to 10 times is possible, contributing to reduction of machining time and improvement of accuracy.

(The effect varies depending on the workpiece, workpiece, and condition.)

・Prevention of clogging of jaws by cavitation phenomenon

Secondary vibration when fine bubbles (bubbles less than several hundred nanometers in diameter) can be blown are constantly washed inside the pores, preventing clogging of the pins. As a result, the cutting edge is maintained, continuous grinding of several tens of microns is also possible without requiring sharpening even with # 2000 high mesh.

|

Material of work material |

SKD11(HRC57) |

|

Workpiece outline |

200×200×20 |

|

Usage Insertion |

WA60K |

|

Total grinding amount |

0.1mm |

|

Cutting amount |

0.05mm |

|

Machining time |

165 seconds |

|

Surface roughness |

Ra1.177μm |

※The effect of GRIND-BIX differs depending on the model, processing work, and use.

GRIND-BIXコアンダ効果