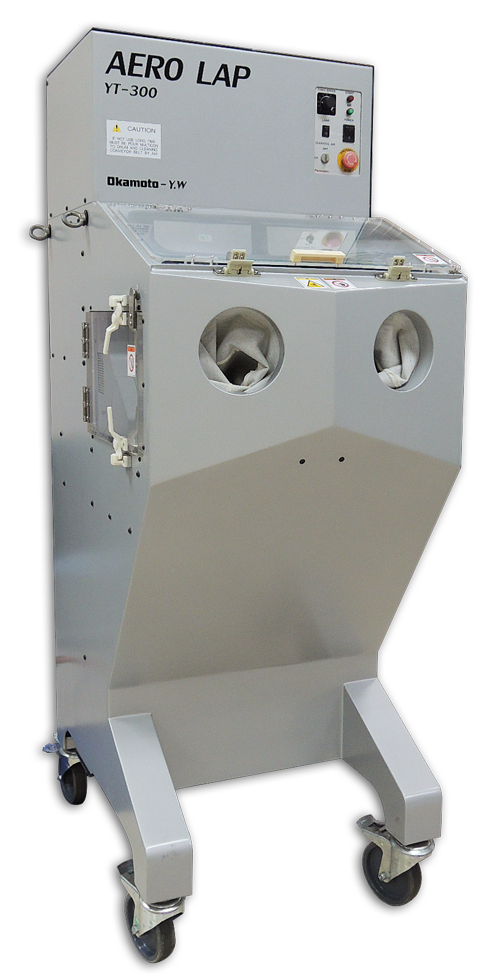

AERO LAP - Mirror Finishing Machine (Lapping Machine) - |

Mold & Die Cutting tool Coating Resin, GlassEnables the unique and innovative lapping technology. Instantly laps dies with complex shapes to superfine finish, maintaining their shapes and sizes. AERO LAP effects AERO LAP produces various effects in the products and the work environment as follows. ●MOLD&DIE, CUTTING TOOL and COATING ⇒ |

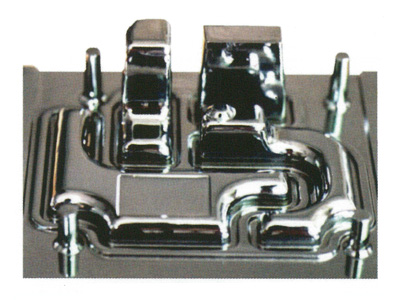

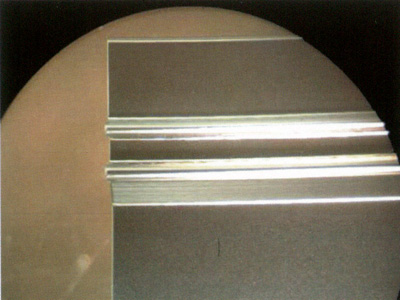

Cold forging die lapped by AERO LAP |

|

Mechanism Multi Cone, abrasive media, consisting of abrasive particles and moisture, is elastic and adhesive. In the lapping process, Multi Cone slides on the surface of the workpiece at high speed. The sliding frictional force thus generated helps to polish the surface to a mirror finish. |

|

AERO LAP effect of Coating

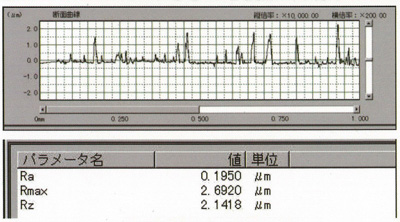

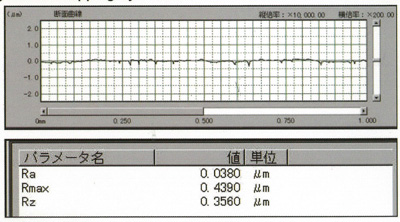

■ Thirty-second lapping by AERO LAP YT-300

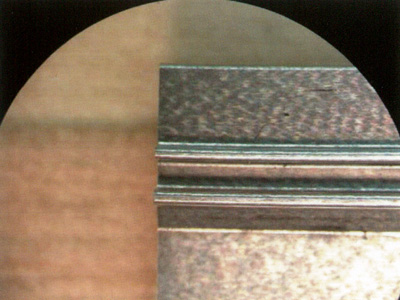

■ Carbide / special-shape PUNCH

■ Other