Okamoto promotes the start-to-finish integrated production system. |

|

| Wooden Pattern |  |

Casting |  |

Painting |  |

Machining |  |

Assembly |  |

Shipping |

| Sheet Metal |  |

Cleaning |  |

Painting |  |

It is Okamoto's motto to provide high-quality and high-precision products.All casting of machine base are manufactured from wooden pattern.

|

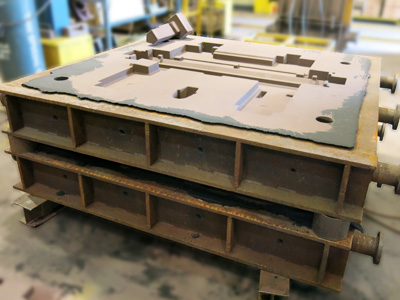

Wooden Pattern |

|

|

|

Casting is an important element for machine tool; wooden pattern is essential for castings.

Okamoto design the wooden pattern in house to produce rock-solid castings which is a critical component to a surface grinder. There is strong point to make Grinder with rigid frame.

Type of wooden pattern: Long-lasting wooden mold, Resin pattern, Foam pattern

Casting |

|

|

|

Okamoto manufacturing products from cast iron. It enables improvement quality, cost reduction and shorter lead time.

It is possible to correspond the base of customers demand.

Production capacity: 1,800ton /month (both old and new factories)

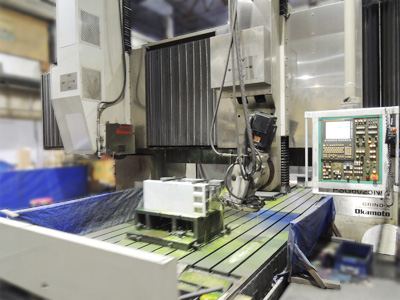

We own one of the largest surface grinding machine in Southeast Asia. |

Machine: |

|

|

Assembly (Scraping) |

|

|

|

|

|

|

|

A scraping process to reduce the resistance of the slideway surface is essential to the long term peak precision of a surface grinder. We inherit the unique scraping technique and pass on to the next generation.

Production capacity: max.120units /month

Environmental Activities |

|

|

|

Casting was newly formed in the Thai plant , We are aiming to clean foundry, it has become a dust and dust collection of gas, plant that was also friendly to sand recovery and reuse and environmental equipment.

|