Our products are useful for the various fields such as Automotive industry.

|

* Click on the parts name to see examples

|

|

|

|

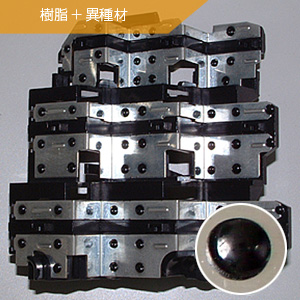

► Plastic + Plastic (same materials)

|

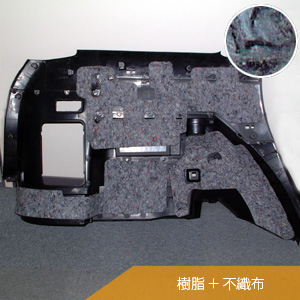

► Plastic + Nonwoven fabric

|

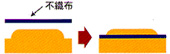

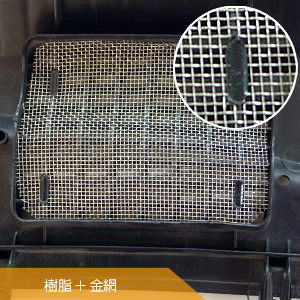

► Plastic + wire mesh

|

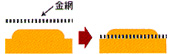

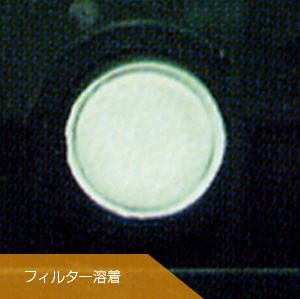

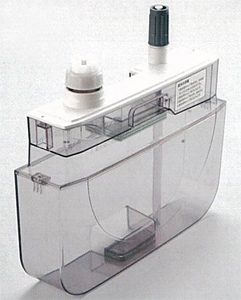

► Plastic + Membrane filter

|

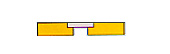

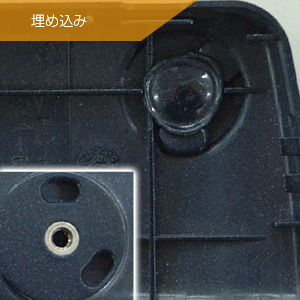

► Embedding

|

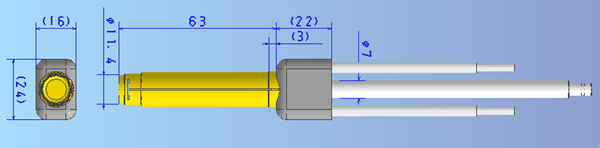

► Insert nut

|

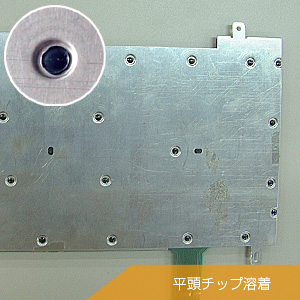

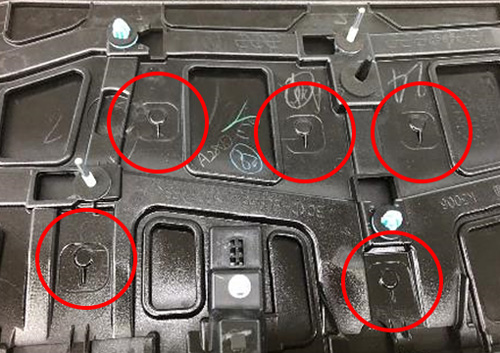

► Flat head tip staking

|

► Sealing hole

|

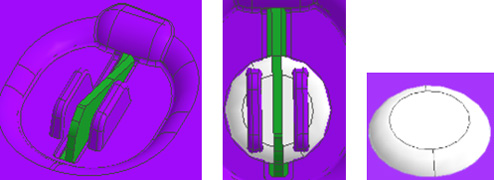

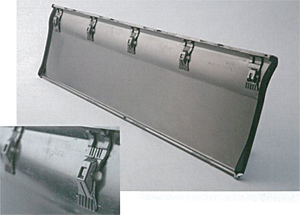

► Lens periphery crimping

|

|

|