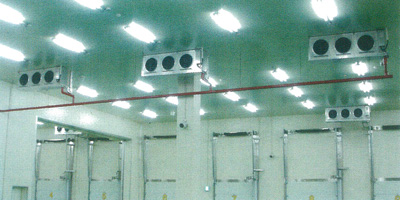

We will meet customer needs to control temperature, humidity, air flow for the warehouse and production line using the refrigeration and freezing technology we have cultivated over many years.

Low temperature system is the core business area which Tokyo Sanrei Mahajak (TSM) is focusing on. For refrigeration and freezing equipment, the first priority is to maintain the required temperature and humidity inside the cabinet efficiently and reliably. On the other hand, low temperature air conditioning equipment is designed and constructed with due consideration to ensure the safety of the product and prepare the working environment for workers.

Also, refrigerants are expected to shift from chlorofluorocarbons to substances with low global warming potential (GWP) due to ozone depletion and global warming problems. Therefore, TSM is working on refrigeration systems with alternative natural refrigerants such as ammonia (NH3) and carbon dioxide (CO2) for sustainable environment.

TSM works with customers closely and proposes efficient and up-to-date equipment to realize customers’ new construction plans as well as improvement plans.

|

Low Temperature Engineering Proposals |

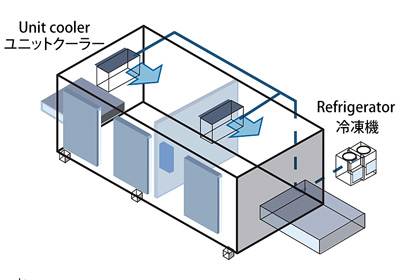

■ Freezing Tunnel |

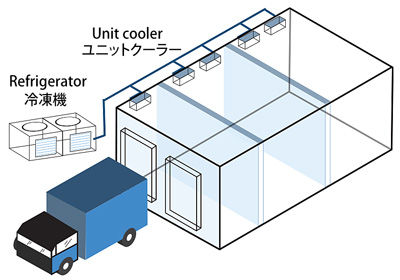

■ Cold Storage |

|

|

・Regular freezer |

・Anti-explosion / Regular specification |

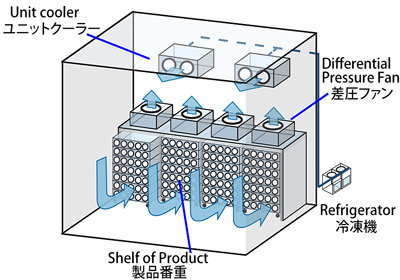

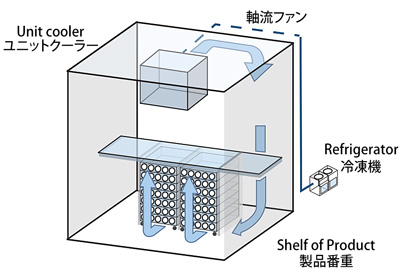

■ Differential Pressure Cooling |

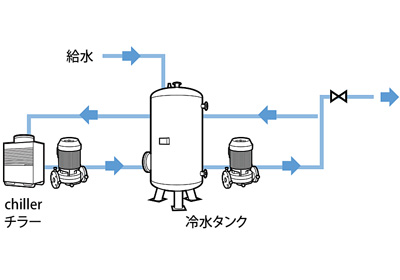

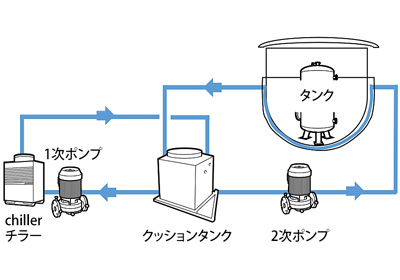

■ Chilled Water |

|

|

・Storage temp, Product core temp, Cool down time |

・Cold water around 1℃ |

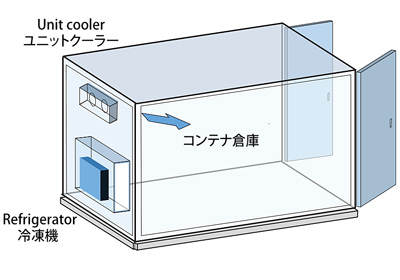

■ Freezing & Refrigerating Container |

■ Tank Refrigeration |

|

|

・Air-cooled Refrigerator unit |

・Cold insulation, Cool down, Fermentation |

■ Rapid Cooling |

|

||

|

・Chamber temp, Product core temp, Cool down time |

|

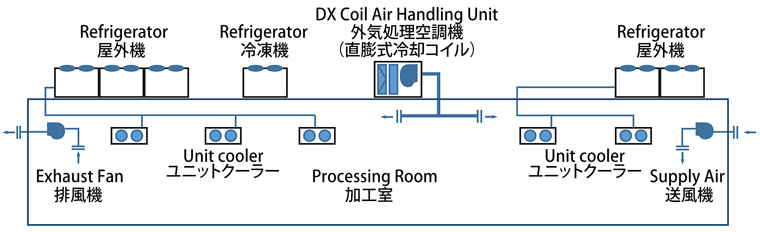

■ Low Temperature Air Conditioning |

|

・Temp/Humidity control ・Cleanliness ・Local ventilation ・Chamber pressure control ・Air flow control |

|

Application for Food Industry |

|

Construction Results (Thailand) |

■ Construction Results |

||||||||||||||||||||

|

|

Construction Results (Japan) |