► Advantages of using this system |

|

★ |

The quality of the molten metal is good because the water temperature does not reach high temperatures due to direct heating. |

|

★ |

Energy-saving when used in combination with gas.In some experiments, overall fuel consumption was halved. |

|

★ |

The temperature of the holding chamber is kept low and the operating time of the preheating burner is shortened. |

|

★ |

You can directly control the temperature at the outlet, so the water temperature is stable and the quality is stable. |

|

★ |

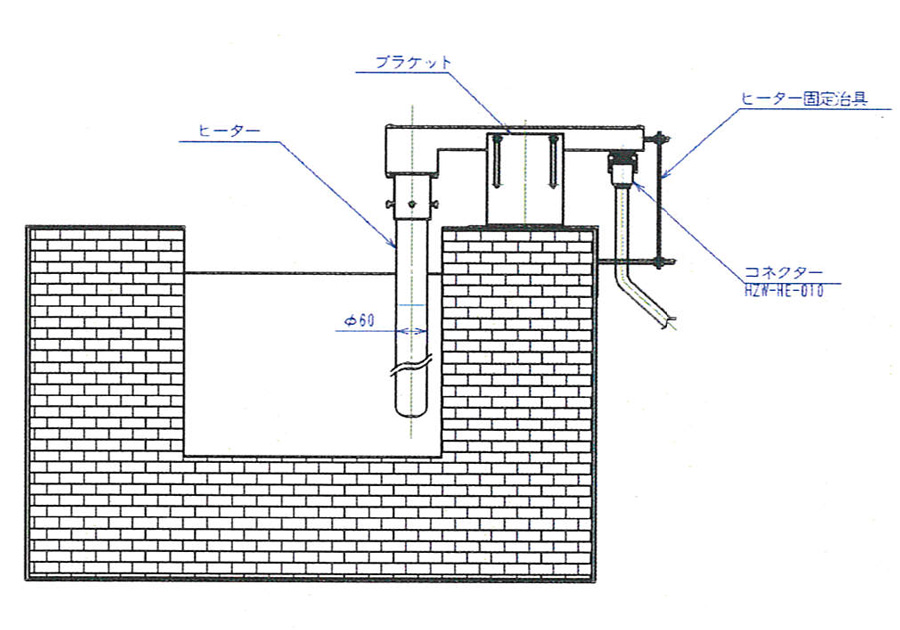

Easy to install on current equipment |

|

★ |

Reduces the combustion time of the burner, which reduces CO2 and reduces the generation of oxides. |

|

★ |

The amount of flux consumed is reduced because the generation of oxides can be reduced. |

|

★ |

The heater is nichrome based and has a 3-phase power supply, which reduces initial equipment costs. |

|

★ |

Until now, there was no heat source that put heat into the pumping part, but this is now possible with the new heater. |

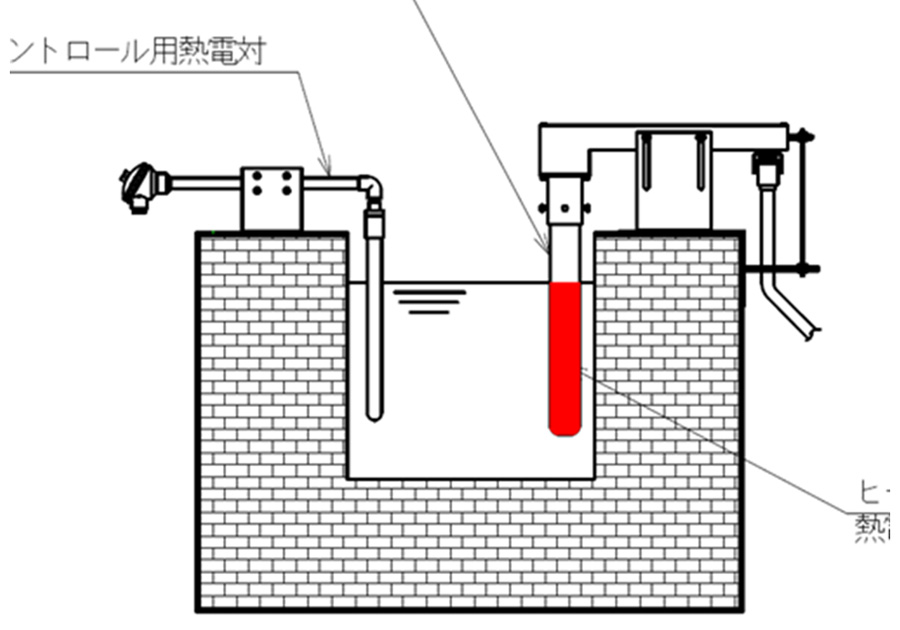

► Providing a system using Japanese technology (patent pending) |

This heater system can be installed and started on the same day on-site (control is via SSR and PLC). The heater is also sold separately, with integrated lead wires and a control box.

|

|

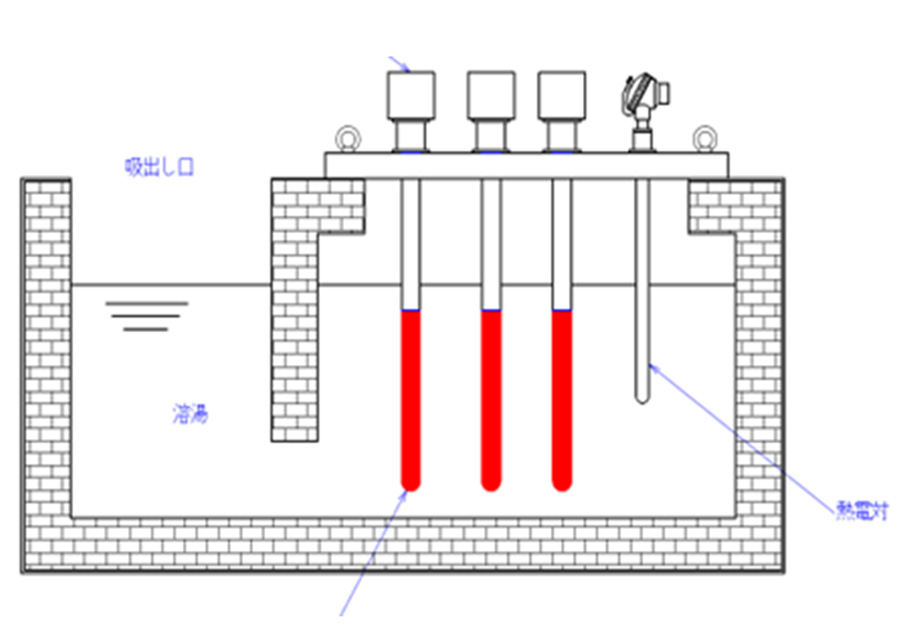

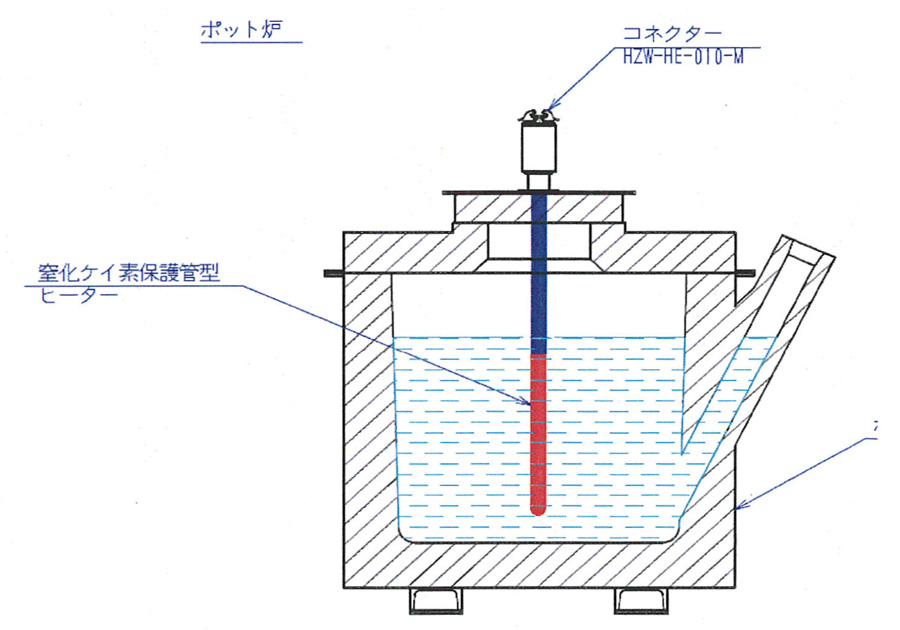

Silicon nitride type immersion heater

|

|

Total tube length |

450-1400mm |

|

Connection voltage |

available in 200V, 380V, 480V, and three-phase |

|

Heating capacity |

2.7 kW per 100 mm Example: 13.5 kW for 500 mm HL |

〇Since it is connected to the control panel by a connector, it can be easily replaced.

〇The outer tube of the main body is made of silicon nitride with good thermal conductivity and is less likely to corrode even molten aluminum.

〇Special nichrome electric heater is embedded.

〇Integrated unit type allows for easy removal and installation.

〇Equipment costs are lower because the control is SSR control.

〇The shape corresponds to the shape of the extrusion, and it is possible to design freely including the electric capacity.

Change the molten metal temperature from KEEP to RISE |

|

The overheat prevention circuit does not operate until the set temperature is reached. |

▲Click to enlarge image▲

|

|

Cable part〇Easy to carry |

|

|

Control box

|