Applications |

We are an OEM using metal injection moulding (MIM), specialised in small complicated designed components serial production. Our originally developed μ-MIM® technology defies MIM limitation. These are only some application examples. Please feel free to contact us for further details.

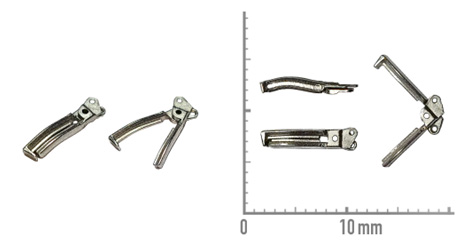

Forceps <Stainless steel 17-4PH> |

|

|

Disposal use has been realisedThe micro forceps that used for endoscopic operations are very small yet complicated designed, thus, the cleaning and sterilisation procedure are complicated. Our μ-MIM® technology has been realised the stable precise serial production of the forceps, under ISO13485 certified quality aμ-MIM® technology realises thin wall thickness, less than 100 μm, components stable serial production. We deployed fine powder, the average powder size is around 5μm or smaller, to realise the thin wall stable production.ureance system, and now they are operated as disposal use. |

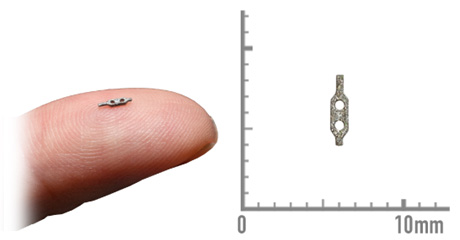

Decorative piece <Titanium> |

|

|

Stable serial production of tiny Ti partsTitanium is one of the difficult to process material in machining but also in powder metallurgy. Ti is very reactive with oxygen in elevated temperature thus the atmosphere control during the sintering process is important. The smaller Ti parts have higher surface ratio to its volume, it is more difficult the stable mass production. μ-MIM® technology realised a few mm size Ti part precise serial production. |

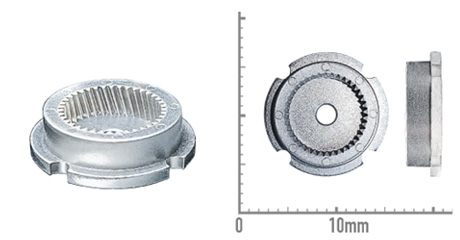

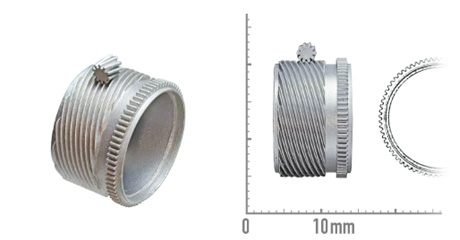

Internal helical gear with a lit <Stainless steel 316L> |

|

|

The impossible design by machiningIt is difficult to produce the internal helical gear by machining, moreover, it is impossible to compose the gear teeth until the very bottom of the lit. We apply not only the precisely tooled mould but also the originally developed feedstock for small complicated designed gear production. Our μ-MIM® technology reralises precise serial production of small gears. |

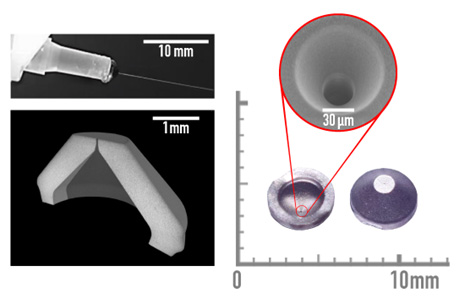

Micro nozzle tip <Stainless steel 316L> |

|

|

Stable production of fine through holeThe hole diameter is 30μm and 200μm length at the centre of the tip. This feature is gained at the as-sintered, without any post processing. Therefore, not only the smooth surface finishing with no polishing media contaminate, but also the stable positioning of the hole is realised in our μ-MIM® serial production. |

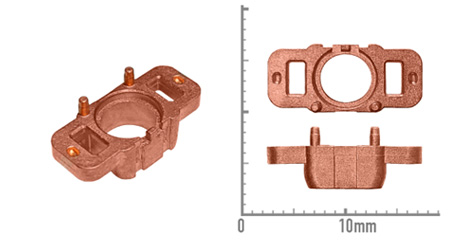

Heatsink <Copper> |

|

|

Stable serial production of Cu productThere are very few MIM manufacture accepting the Cu part serial production, since the reduction process in MIM is difficult. μ-MIM® technology has developed a feedstock for Cu production and realises small complicated designed Cu parts stable serial production. |

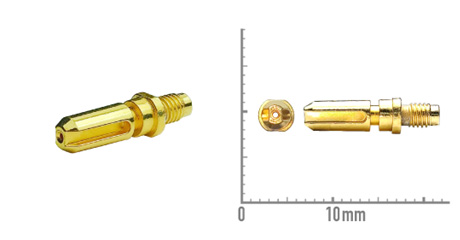

Micro nozzle <Stainless steel 17-4PH> |

|

|

Stable precise serial production for medical inductry applicationIt is commonly employed machining for nozzle manufacturing since it requires highly precise control in tolerance, however the productivity is suppressed in small nozzle. μ-MIM® technology realised high productivity with highly controlled quality and satisfaction of tolerance requirement in small complicated nozzle production. |

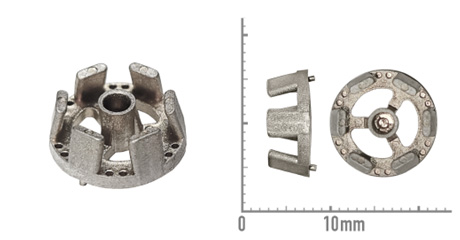

Yoke <Stainless steel 410L, Fe-3Si, Permendur etc.> |

|

|

Precise serial production with satisfying magnetic propertyμ-MIM® technology has realised small complicated soft magnetic metal component serial production with achieving the best magnetic properties in powder metallurgy. There is no post heat treatment required, thus the ideal net shape production at as sintered is promised. |

Integrated gear <Stainless steel 316L> |

|

|

Precise in size and positional toleranceWe μ-MIM® technology has experienced various type of integrated gears, such as different specification multi step gears, shaft and gear. The highly controlled small gear manufacturing is included gear analysis, e.g., teeth line 3D measurement and comparison to CAD. |

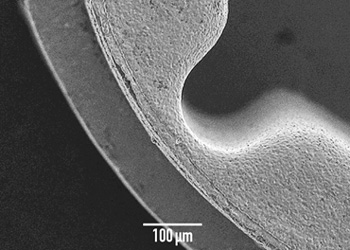

Thin wall structure <Stainless steel 316L> |

|

|

Serial production of less than 100μm thickness designμ-MIM® technology realises thin wall thickness, less than 100 μm, components stable serial production. We deployed fine powder, the average powder size is around 5μm or smaller, to realise the thin wall stable production. |

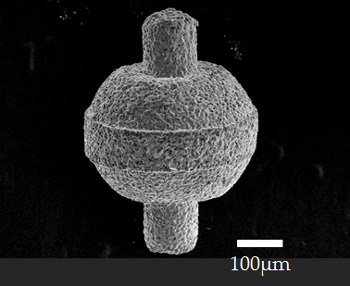

Micro wheel <Stainless steel 316L> |

|

|

The overall size of less than 1 mm metal componentWe have experienced serial productions of smaller than 1 mm size metal component, that is difficult to handling. μ-MIM® technology has developed feedstock, mould, injection moulding parameter, furnace, sintering parameter and measurement system for small metal component serial production. |