Precision Cutting Wheel |

|

| Processing with |  |

|

A Type of precision processing method where a cutting wheel spinning at high speed is used to grind the material being processed via the extremely hard particles (abrasive grains) which the wheel consists of. The material can be gently processed without being damaged, while the superior precision cutting realizes a finely finished surface. Characteristics

|

|

|

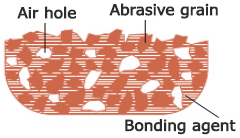

Mechanism The body of the cutting wheel, as revealed by the illustration on the left, consists of 3 elements: abrasive grain, bonding agent, and air hole. The large number of abrasive grains on the working surface grinds the material away little by little because of their roughness. The abrasive grains gradually dull, get crushed, and eventually come away from the working surface. However, as grains fall off new abrasive grains sequentially appear on the surface. This means that the edge of the wheel remains at the end, although the external diameter does decrease in size. |

|

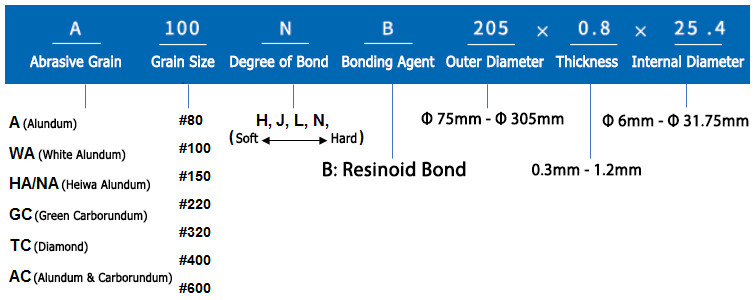

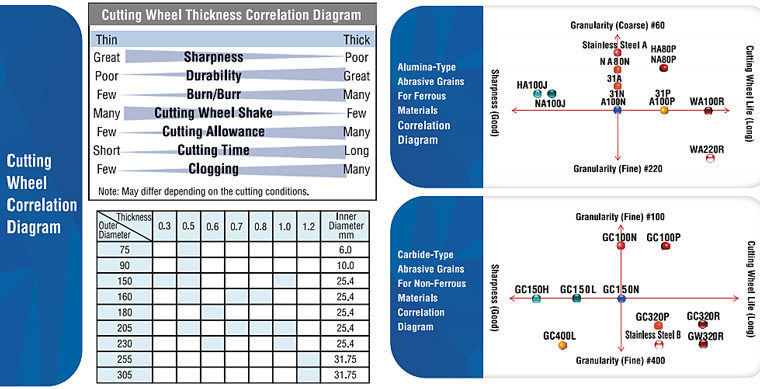

■ Labeling and Characteristics of Cutting

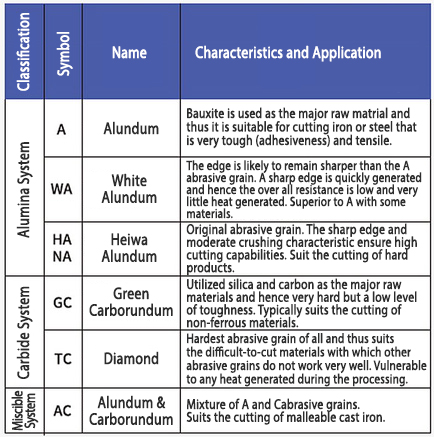

■ Abrasive Grains

We have the following types of abrasive grain available, which depends on the material to be processed.

|

|

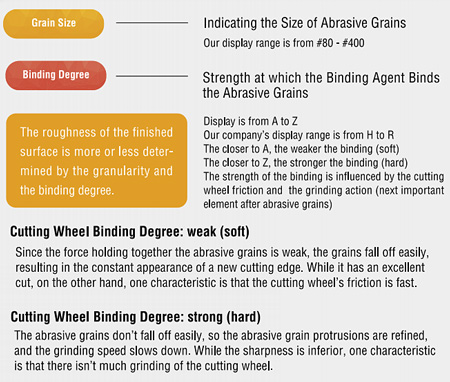

■ Grain Size

The grain size denotes the size of the abrasive grains used, with #80 through to #600 being available. The size of the grain and degree of the bond decide the roughness of the finished surface of the material to be processed.

■ Degree of Bond (Hardness of cutting wheel move)

The degree of the bond denotes the strength of the bonding agent to the abrasive grains. The degree range from A to Z, with the range we have available ranging from H to R. The degree of the bond is the weakest (softest) with A and the strongest (hardest) with Z. The degree of the bond affects its abrasive qualities, and hence the cutting effect of the cutting wheel, and therefore is the second most important factor after the abrasive grains themselves. A weak (soft) bond means that the wheel cuts sell but wears out relatively quickly. A strong (hard) bonding means that not many abrasive grains so come off and hence the cutting speed decreases as their roughness becomes dull. It therefore has less cutting capabilities but is quite durable.

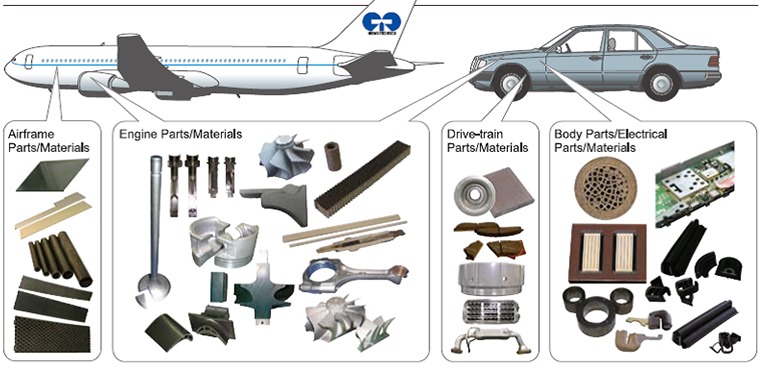

| Examples of |  |

Utilization |

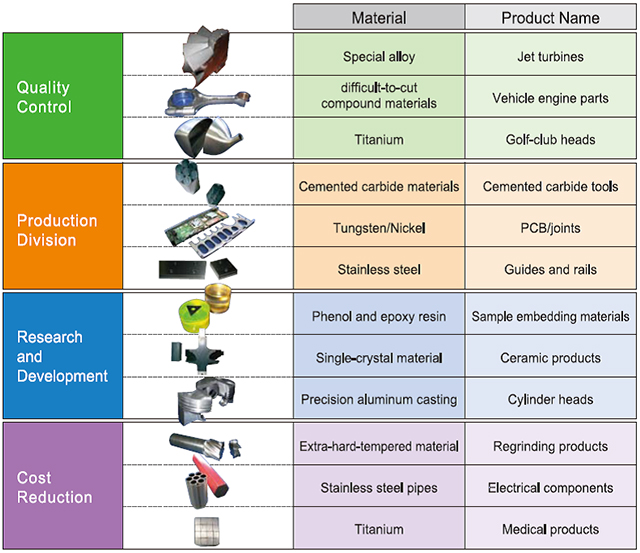

| Application of |  |

(Material / Product Name) |

|

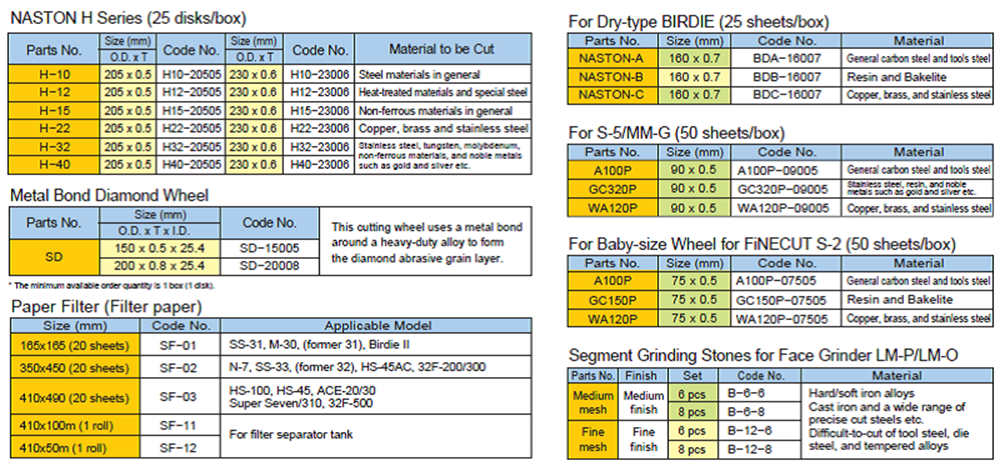

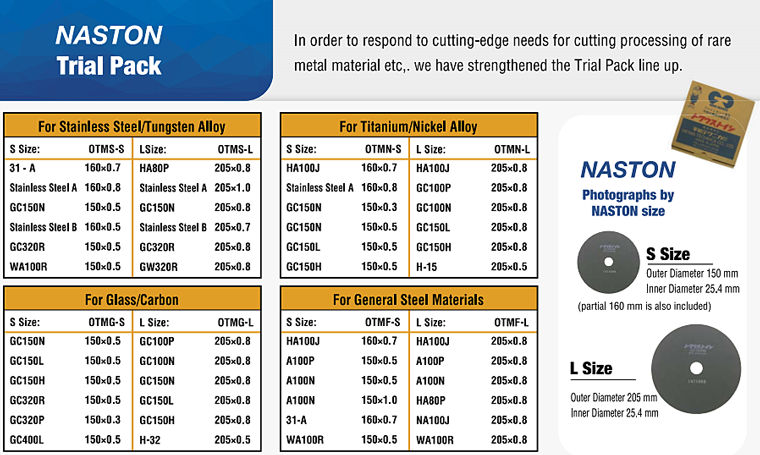

Products Line-up |

|

Sample Application of Standard Models |

─ NASTON Cutting Wheel(Φ150~230) Standard Cutting Wheel Selection Examples ─

Standard Products Other Optional Products

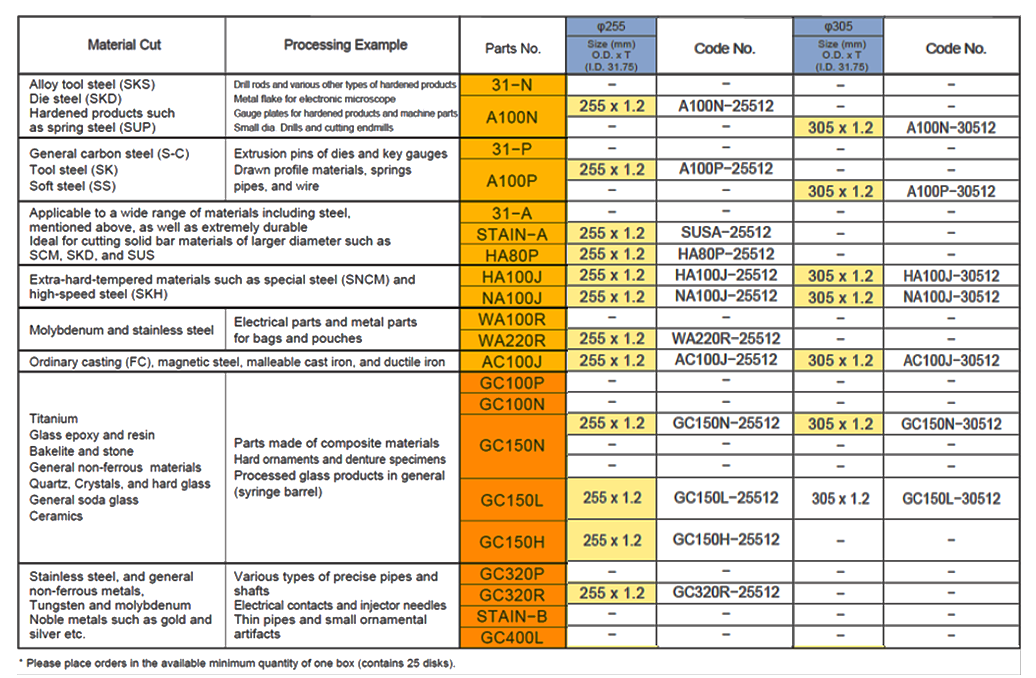

─ NASTON Cutting Wheel(Φ255~305) Standard Cutting Wheel Selection Examples ─

Standard Products Other Optional Products

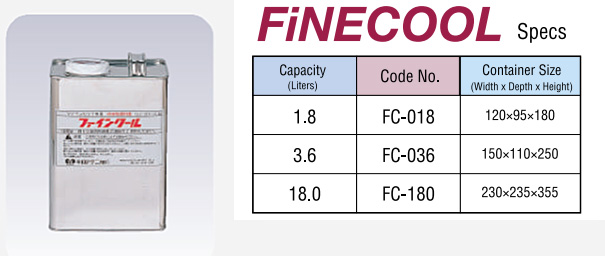

Water Soluble Cutting fluid Exclusively for NASTON GOLD/NASTON

Its superior permeability/lubricity/cooling characteristics enable clogging to be prevented, thus prolonging the useful lifespan of the cutting wheels. It also features an improved antirust effect. Dilute FINECOOL about 40 times.