Member introduction

GUNMA SEIKO (THAILAND) CO., LTD.

Utilizing technical cold forging technology, we are leading a new era of aluminum and steel.

Gunma Seiko has been consistently working on establishing cold forging technology since be established in 1968 by Mr.Takachi Marumo.

Gunma Seiko's management principles is "The drive to challenge and the sincerity of service" we have been passionate about challenging new technology as a group of selected engineers.

The potential as a material hidden in aluminum, such as weight reduction and strength enhancement and utilizied processing technology of cold forging which is plastic working.

Based on two of above, we deliver high-quality products to a wide range of fields such as motorcycle and automotive, hydraulic equipment, leisure products such as fishing gear and boat, and OA equipment.

High Precision Cold Forging Products

THE STRENGTH OF GUNMA SEIKO

【VA/VE idea】

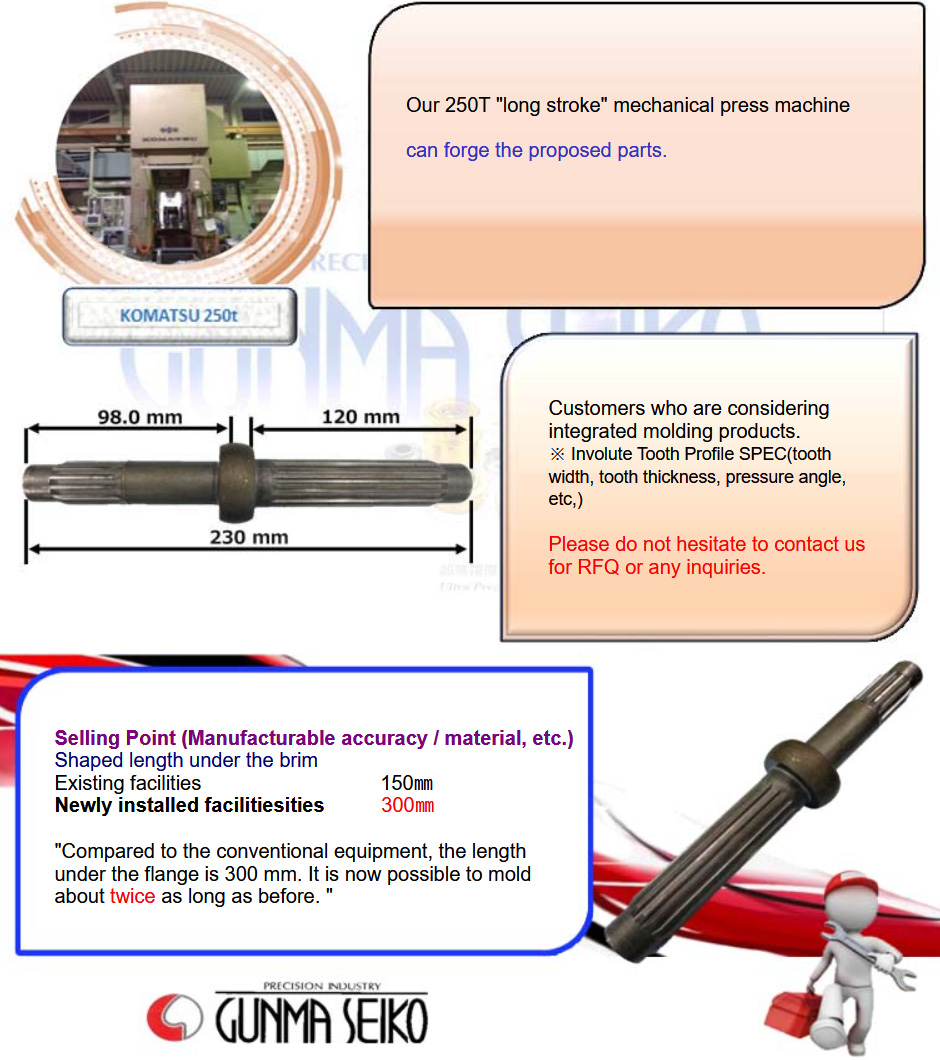

Forging of Long shafts with Splines on either sides.

GUNMA SEIKO (THAILAND) CO., LTD. >>